Frontline Wildfire Defense - System 2

Spanner is proud of the outcome and thrilled for Frontline’s System 2 to be recognized as one of TIME Magazine’s 2025 Best Inventions.

The Objective

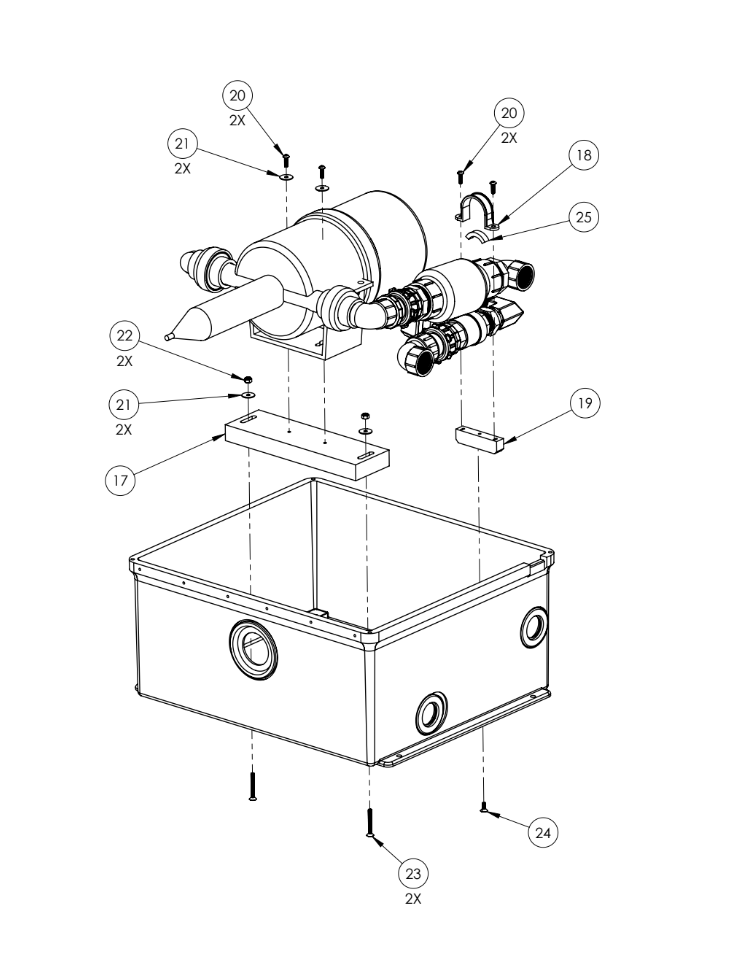

Frontline Wildfire Defense, as part of their mission to protect homes, families, and communities from wildfire, sought to transition their custom-built fire defense systems to a modular, mass-producible design. This required meticulous attention to detail, precise engineering, and seamless coordination with manufacturing partners.

Frontline approached Spanner, seeking expert engineering support on a staff augmentation basis. Our team refined the design for component mounting, identified the appropriate hardware components to meet specifications, and optimized the design for manufacturability. We established a robust part numbering protocol and created comprehensive drawing sets and RFQ packages to facilitate efficient manufacturing. We conducted rigorous quality checks, identifying and resolving potential issues with tolerances and fit. We also sourced enclosure vendors capable of meeting engineering requirements, assisted in CM selection, and made key contributions to the assembly and testing of the initial prototype.

The Outcome

Through a collaborative approach and meticulous attention to detail, Spanner helped Frontline successfully transition to a modular system. This transition has enabled them to:

Increased production capacity: By moving to a mass-production model, Frontline significantly increased the availability of their life-saving systems.

Reduced installation time and costs: The modular design streamlined installation, making it quicker and more cost-effective.

Enhanced product consistency: Standardized manufacturing processes ensured consistent quality and performance across all units.

“Spanner’s expertise was invaluable in bringing our vision to life. Their attention to detail and collaborative approach were instrumental in overcoming the challenges of this complex project.”

Key Takeaways

Spanner delivered impactful results through a collaborative and detail-oriented approach. By seamlessly integrating into the Frontline team, we successfully transitioned their fire defense system to a modular design, enabling increased production capacity, reduced installation costs, and enhanced product consistency. This project demonstrates the value of Spanner's staff augmentation model in providing flexible and scalable engineering support to clients facing complex challenges.

To learn more about System 2, visit Frontline’s website.

More of Our Work