In Part 1 of this series, we surveyed the elements that comprise a Cost of Goods Sold, or COGS, for a physical, manufactured product, using the journey from raw materials to customers’ hands to map out those elements.

The development journey is similar, except across the calendar instead of the globe. At various sections along the route, important experts & stakeholders need to be engaged and, of course, paid, to get you to the next milestone. In general terms, this is easily understood by clients even if they’re newcomers to the process. However, when it becomes necessary to actually have, for example, a high-confidence development budget to put in front of investors, most clients are at a loss to fill in all the gaps, let alone have the context to support their assertions to investors. At worst, uninformed guesses are grossly optimistic, leading to an underfunded enterprise at much greater risk of failing to launch.

Before getting into the details, it’s important to understand that these budget estimating exercises we do at Spanner are designed specifically for generating realistic and conservative numbers for fundraising and business modeling purposes. Our agreements with clients around a scope of work grow out of parallel but distinct conversations, ensuring among other things that we keep a keen eye on moving ahead as efficiently as possible once launched into the work.

Development Team

The first, and typically largest, portion of the budget to address is the development team. Even before any design or engineering has begun, we’ll have a very good sense, based on the nature of the product, of what roles will be involved during each phase of development, and at what scale. While this happens at a fairly coarse resolution, using months not weeks for instance, the resource requirements tend to average out reliably to give us sound estimates across the program.

We’ll also take into account a client’s plans for building their own internal team, adjusting resource costs along the way to reflect whether outside resources are enlisted versus employees. There’s no one right answer on this front; business leaders need to put resource costs in the larger context of their business model and long-term strategies for what type of company they are becoming. An ambitious product roadmap for building a successful brand might point to recruiting a comprehensive and fully staffed team, while demonstrating the viability of core IP for acquisition or licensing purposes can suggest maintaining a very lean internal team, for example.

With regards to resources, we also reserve line items for roles not directly related to product development, but often critical for the viability of the enterprise, including legal counsel, accounting, and administrative, as well as founder-level or C-suite roles that may contribute, such as finance, marketing, and operations.

Capital Costs & Expenses

The next portion of the development budget we consider are capital costs and expenses. In our world, the dominant source of capital cost is the array of custom tooling and fixtures needed to fabricate parts in production. While tooling of some form is created for various types of parts, by far the most common and expensive are tools for injection molding of plastic. It’s common to see individual tools, aka molds, cost several tens of thousands of dollars each, with multiple parts pushing tooling budgets easily into six figures for even modestly sized devices. Depending on the strategic objectives for the initial production quantities, we have opportunities in the earlier design phases to ensure tooling budgets reconcile with company goals by considering mold cost drivers like part complexity, production velocity, and life expectancy for the tools.

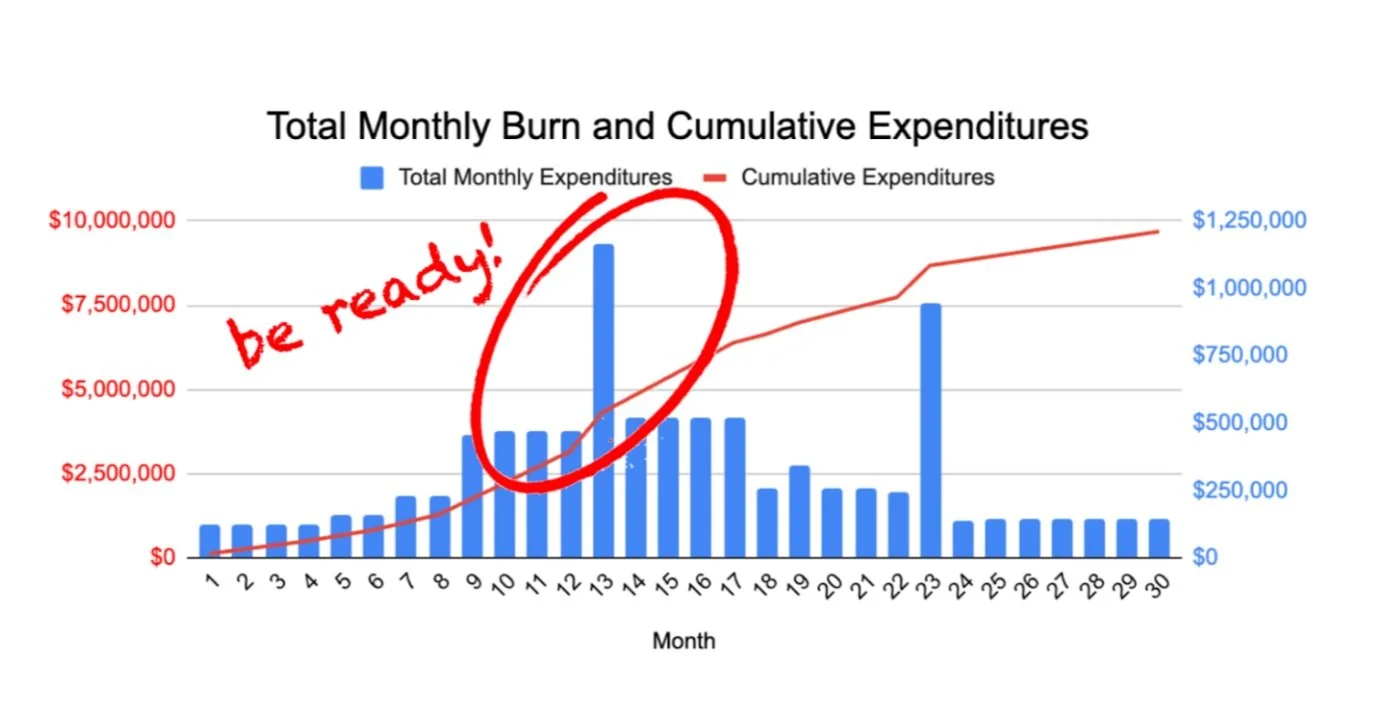

While the costs associated with the development team are spread over time, tooling and procurement costs typically present a significant spike in cash flow. For example, we commonly see contract manufacturers ask for 30-50% of tooling costs upfront, along with 50-100% of raw materials procurement costs. If your tooling costs a relatively modest $50,000, and your PO is for 10,000 units with a $100 BOM cost, you’re looking at something like $325,000 due when you kick things off with the CM (assuming ~30% of BOM is materials cost).

Your CM may also add fees for non-recurring engineering, or NRE, expenses to cover the time their engineering and operations teams invest in all the activity leading up to production start. You may also need to spend on independent labs to certify regulatory compliance, software licenses, creating and managing pilot programs, and indirect marketing campaigns, among myriad other expenses.

“To help ensure we navigate this journey as efficiently as possible, we try to build as much context around the design process as we can by asking the big-picture questions early. ”

What is your vision for your new product manufacturing company? Who will you hire when? What roles will you contract out to service agencies, like Spanner, in the meantime? Who will handle your logistics, distribution, customer service & warranty? Who will build and execute your marketing plan? It’s OK and common not to have all the answers in the early stages. The important thing is to get these critical questions on the table early on as an effective way to mitigate risk.

Besides the obvious nature of things like lower COGS yielding higher margins, and lower development costs reducing investment needs, Spanner can highlight and exploit more subtle opportunities for greater synergy between a business plan and a development strategy. We’ll delve into that in Part 3 of this series.

Arne Lang-Ree is co-founder and CDO of Spanner.

An innovator, thinker and deconstructor, Arne challenges himself and Spanner’s clients to bring sustainable and responsible products to life. Born in Norway, Arne was inspired early by his engineer father to look at things twice. At an early age, he was imagining inventions that ultimately inspired him to earn both his BSME in Mechanical Engineering and MSE in Product Design from Stanford University. Arne has since racked up more than 30 years of product development and mechanical design experience in a wide range of product markets and with globally recognized brands. Arne is rarely without his trusted canine sidekick, Penny, and the duo can be found at the Spanner office creating together or walking the Silicon Valley for inspiration.

Interested in learning more about what it’s like to collaborate with Spanner?