Clients often ask us to help sort out a particular conundrum they face: how to devise the cost to manufacture their product on which to build their business model, before the product has been designed? The solution has as much to do with understanding what goes into that cost as with conjuring valid estimates.

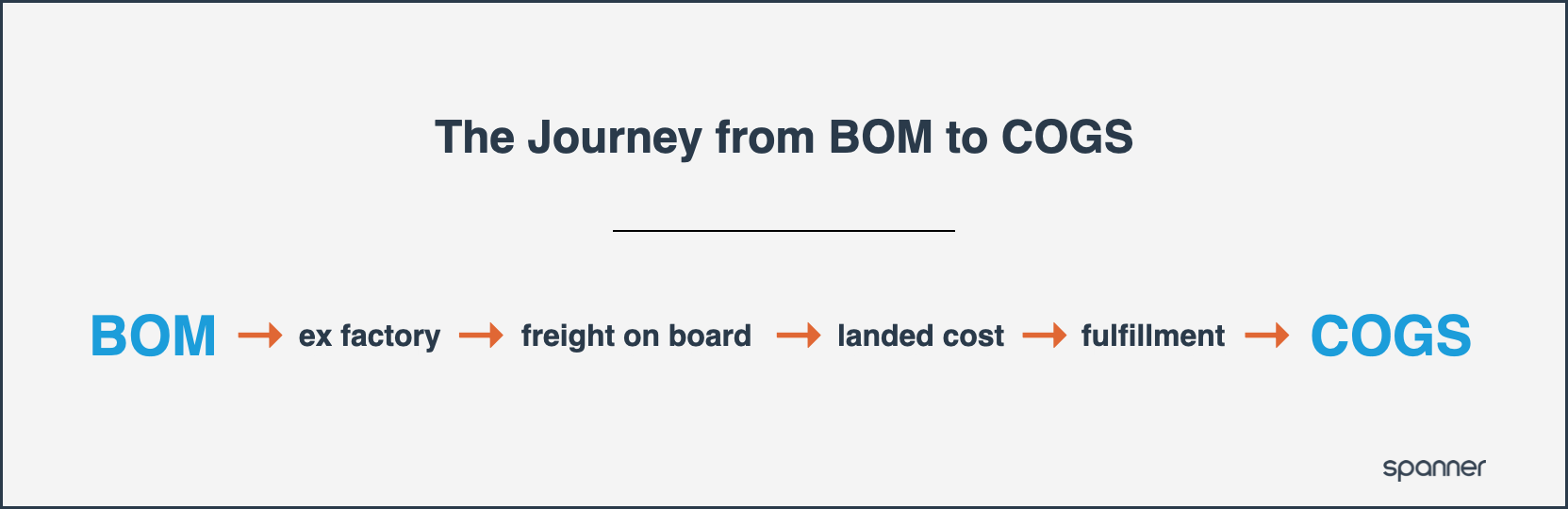

Everyone understands that each individual part comprising a product costs money, for the raw materials, for the fabrication of the part from those materials using specialized tools and machines, and maybe for a printed circuit board assembly. Likely also included are “off-the-shelf” parts like electrical connectors, sensors, buttons, motors, displays, speakers, batteries, etc. Experienced engineers are usually pretty good at estimating what this list of parts will include (referred to as the Bill of Materials or simply BOM), and roughly what these parts might cost at volume. This initial “costed BOM” estimate is only the first step in coming up with the true cost of getting your product to buyers and consumers to then build a robust business model around the more comprehensive number, the Cost of Goods Sold, or COGS.

The mix of ingredients in product COGS is not tightly defined across industries or types of businesses however. Business leaders need to decide how best to account for myriad costs to draft a robust model optimized for their particular business. The template model Spanner has created groups these costs in descending order of convention based on our experience working with nearly 500 clients over the years. A client can simply draw the line between groups where it makes sense for them, knowing prospective investors or stakeholders won’t be surprised by what’s included or not.

The first of these groups produces a number known as the ex-factory cost, adding to the BOM cost everything else it took to get your product through the loading dock door and into a container, like assembly labor, quality testing, and pack-out. Not to be overlooked is the cost of the product package, as well as the contents of that box other than your product; printed collateral, baggies, dunnage, maybe a USB cable, etc. Some number of these packages then typically share the cost of a master carton, the large corrugated box that protects your packaging and makes shipping more efficient. All of these costs roll up into the ex-factory cost, ultimately what the factory charges you.

A near-twin of the ex-factory cost is “Freight on Board”, or FOB. Depending on how your logistics are configured, FOB and ex-factory might be the same number though historically FOB includes local freight charges to move your goods from the factory to the port and on board a ship. Over the years, these front-end logistics costs have become bundled by the ocean freight carriers who may now include the local freight in their rates as your product is loaded directly into ocean containers at the factory instead of a truck.

The next waypoint is referred to as the Landed Cost, which starts when your ship has come in and your container off-loaded, adding a share of the ocean freight to each of your products in the container. Keep in mind that ocean freight rates are calculated by cubic volume, so space-efficient packaging can impact your COGS. Once a container lands on the back of a truck at a domestic port, a third party logistics company, or 3PL, typically handles things to get your master cartons onto shelves in a distribution center. Once the goods are in inventory, you’ve rolled up your Landed Cost. You can think of it as the mirror image of ex-factory cost.

The 3PL also operates a distribution center, providing inventory management services for a number of client businesses to get products into the hands of consumers. For example, a customer order on your website may go directly to the 3PL, their staff pulls products from shelves, packs everything up for shipping (maybe in your branded box or pouch), applies labels, and hands it over to a delivery company. This is collectively called fulfillment costs. Finally, depending on how much of that delivery charge you pass on to your customers (free shipping, yay!), you’ve now reached your delivered product cost, the point where we at Spanner typically draw the line and call it COGS. Subtract that from your retail price and you have your gross margin.

The delta from BOM cost to COGS at this juncture can be on the order of 40%, a critically significant number relative to your gross margin.

Three additional groups of numbers are sometimes also considered part of COGS. The first is support costs, what it costs you to deal with returns and warranty claims. Then there are fixed costs like tooling and set-up charges, which may be amortized over a quantity of products or period of time. Finally, R&D and SG&A costs associated with getting your product to market are also sometimes amortized into COGS.

Ex-factory, FOB, Landed, Fulfilled, Delivered - someone gets a cut at every step along the way. Nothing much has changed since the golden era of the Great Silk Road, or later when Ferdinand & Isabella paid a fortune to have Columbus look for a sea route to the Spice Islands and Asia to lower the COGS on imports. It’s up to you to consider the value of every adder to your costs, building a robust business model that can withstand fluctuations and variables in your COGS.

Of equal importance to COGS, your spend on the people and materials needed to carry your product through development into production can be an elusive number to estimate with many variables, and a critical element to get right in a successful enterprise. We’ll take a dive into that pool in Part 2 of this series.

Arne Lang-Ree is co-founder and CDO of Spanner.

An innovator, thinker and deconstructor, Arne challenges himself and Spanner’s clients to bring sustainable and responsible products to life. Born in Norway, Arne was inspired early by his engineer father to look at things twice. At an early age, he was imagining inventions that ultimately inspired him to earn both his BSME in Mechanical Engineering and MSE in Product Design from Stanford University. Arne has since racked up more than 30 years of product development and mechanical design experience in a wide range of product markets and with globally recognized brands. Arne is rarely without his trusted canine sidekick, Penny, and the duo can be found at the Spanner office creating together or walking the Silicon Valley for inspiration.

Interested in learning more about what it’s like to collaborate with Spanner?